Smart Manufacturing: towards a Digital Supply Chain

Superior performance, increased productivity, profitability and competitiveness and the ability to better satisfy customers and ‘predict’ the market. These are the results obtained by companies that invest in innovative technologies. The Boston Consulting Group analyses the leaders of the digital supply chain

For years, companies have exploited digital technologies in the supply chain to improve the level and quality of the services offered and to reduce costs. However, the inability to connect and integrate heterogeneous systems, to provide end-to-end visibility throughout the supply chain and to manage the huge amount of data generated has greatly influenced the results obtained and prevented companies from benefiting from the actual potential of a digital supply chain. Today, thanks to more widespread availability and greater dissemination of technology, including cloud solutions and sophisticated analytics systems, companies are ‘rediscovering’ interesting returns on investment in Smart Manufacturing projects, especially in supply chain management.

A recent study conducted by The Boston Consulting Group (BCG) revealed that the most innovative companies, i.e. the ‘leaders’, in the field of digital supply chain management are seeing their productivity grow by at least 10 percentage points. In addition, they have improved their ability to satisfy market demand (with response and reactivity times improved by 25%), also by reducing the working capital by 30% on average. These surveys have been conducted on major American companies, mainly based in the USA, therefore it is hard to compare them to European companies, or even less to Italian ones. Yet, besides the individual numerical results, what certainly seems to be interesting to detect are the higher operating margins (with percentages ranging from 40 to 110%) and the lowest “cash conversation cycle” levels [i.e. the days it takes for a company to convert its resources – goods, products or services – into cash – Ed.], reduced by between 17 and 64% for the majority of leading companies.

What are the ‘leaders’ doing?

On the basis of several studies, the BCG has drawn up a kind of ‘handbook’ by working alongside a dozen leading companies, which, for a long time, have been following a Smart Manufacturing approach focused on the digital supply chain, obtaining the above-mentioned results.

1) Correcting performance gaps

Several leading companies have chosen to use new digital technologies, also to support seemingly simple activities, which nevertheless, are better managed than in the past. For example, the Big data analytics applied to provisioning or warehouse management (activities which today, are still typically handled through conventional ERP modules), which not only allow for an optimized allocation of resources, but also involve better organized work by predicting market demand. Nowadays, a global supply chain generates an impressive amount of data, which has become impossible to monitor for humans. The most competitive companies resort to cognitive systems such as machine learning and artificial intelligence to further increase their performance (e.g. through digital systems for managing order-to-cash processes, which use sophisticated adaptive algorithms to perform up to 95% of transactions, thus leaving only 5% of the task to more conventional systems).

2) Innovating business processes

The latest technologies are helping a large number of companies to ‘change pace’, thereby obtaining much better results in terms of performance, profitability and productivity. The most common example among the companies monitored by the BCG is related to the use of automated systems (from tracking processes to their full implementation and management with the IoT and robots), thereby eliminating manual processes. The most ‘enlightened’ companies have gone as far as developing a kind of ‘control tower’ (a technological platform that integrates SCM and ERP systems with cutting-edge real-time analytical solutions) through which they are able not only to improve the handling of internal processes (by optimizing stocks, improving provisioning, predicting peaks in demand, etc.), but also to offer a better service to customers (predicting delivery times more accurately, as well as offering preventive maintenance).

3) ‘Disrupting’ the supply chain

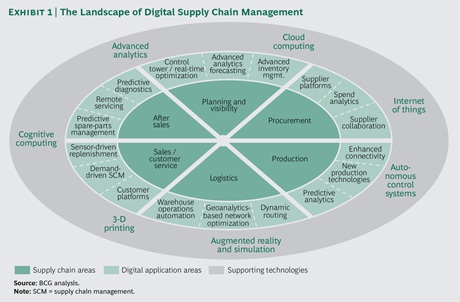

Leading companies use innovative technologies (in Figure 1, the technology ecosystem presented by the BCG, which should serve as a model for the digital supply chain) to redesign operational models and redefine their go-to-market approaches, generating a remarkable growth in revenues and margins. Namely: one of the monitored companies was able to eliminate some distribution channels by using appropriate technologies to develop internal direct-to-customer features, which allowed for savings on distribution costs and an increase in margins (which of course, previously also went to distributors). As we can see in the analysis by the BCG, we now have access to advanced robotic systems at a tenth of their cost a decade ago… and many companies have understood their potential when applied to a small-scale supply chain as well.

Related articles: